The Climatic Chamber that was built and installed in the Heavy Vehicle Simulator (HVS) at the National Laboratory of Materials and Structural Models of the University of Costa Rica (Lanamme-UCR), will simulate extreme conditions of the Costa Rican climate such as humidity, rain, temperature changes and solar radiation, with the purpose of designing pavements that fit the different areas of the country.

The Climatic Chamber was installed in the Heavy Vehicle Simulator (HVS) to emulate in the lab the climatic-mechanical conditions to which the materials are exposed.

Replicating the extreme conditions of nature in a controlled environment such as the Natural Scale Pavements Laboratory (PaveLab) at the Lanamme-UCR, helps to detect possible damages and problems that would occur on the roads throughout their useful life, since, in periods of approximately three months, with the HVS and the Climate Chamber, the wear and tear that a pavement would suffer in about 20 years can be accelerated.

The Climatic Chamber is totally a Costa Rican innovation; it is the only one of its kind in the world. Currently there are no similar equipment in the market at these scales that include variables such as high and low temperatures, solar radiation, humidity and rain simultaneously and for this type of application.

The different climatic varieties can be simulated all at once or independently and will be automatically controlled.

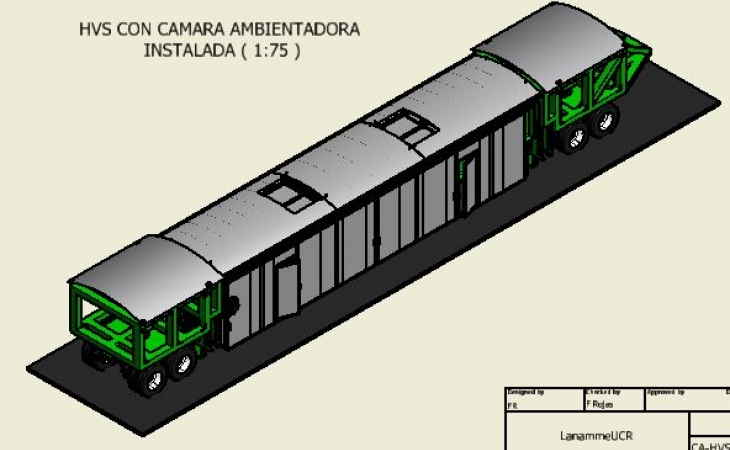

The HVS is equipment that makes accelerated damage tests on pavements at a natural scale. Its dimensions are 75.4 x 10.82 x 11.4 feet (23 x 3.3 x 3.5 meters). The climatic chamber has an approximate volume of 85 m³ (85 cubic meters or 85 000 liters), which is very high compared to similar equipment in the market for other applications.

In addition, the chamber is completely modular since the HVS is mobile; therefore, it can be assembled and disassembled by only three people. In case the HVS needs to be carried long distances, a crane is required to disassemble and assemble the parts.

It works outdoors (like the HVS) and in any climatic condition, without affecting the controlled conditions of the internal chamber. The chamber also confines and attenuates the alternating noise caused by the HVS, as part of its normal operation.

The system allows simulating high and low temperature conditions continuously (24 hours, 7 days a week) during each test with the HVS (from several weeks to a few months without interruption) with temperatures ranging from 0 °C (32 ºF) in the air, up to 65 °C (149 ºF) on the pavement.

It also simulates the cycles where high and low temperatures alternate, in analogy to short natural cycles such as day and night or longer cycles such as the seasonal variations of summer and winter. Initially it will be used to simulate Costa Rica's climatic conditions, although its capabilities are general to simulate other climates and conditions.

In addition to the thermal capabilities of the chamber and to make the climate simulation even more realistic, the equipment has the possibility of simulating rainfall conditions specified by the HVS user in an automated way.

Also, by means of the controlled simulation of solar radiation in the chamber, it can include the physical-chemical effects that radiation has on the pavement during its useful life.

Solar heating and radiation systems will be more energy efficient than those normally used for these purposes.

The chamber was built by a domestic company following the specifications dictated by Lanamme-UCR engineers and it had a cost of over 80 million colones.